Revolutionizing Production: American Assembly Line Advancements

In the annals of industrial history, the American assembly line stands as a transformative force, fundamentally altering the landscape of manufacturing. This article explores the evolution and impact of American assembly lines, delving into the advancements that have shaped modern production processes.

The Birth of Efficiency

At the turn of the 20th century, American industrialists sought ways to streamline production and enhance efficiency. The catalyst for change was the introduction of the assembly line, a concept attributed to Henry Ford. Ford’s innovation involved a continuous flow of production, with each worker specializing in a specific task. This departure from traditional craft-based methods marked the birth of efficiency in manufacturing.

Mass Production Unleashed

The American assembly line revolutionized mass production. By breaking down the manufacturing process into sequential steps, products could be produced at unprecedented speeds. This shift not only increased output but also significantly lowered production costs. The assembly line’s efficiency became a hallmark of American industrial prowess.

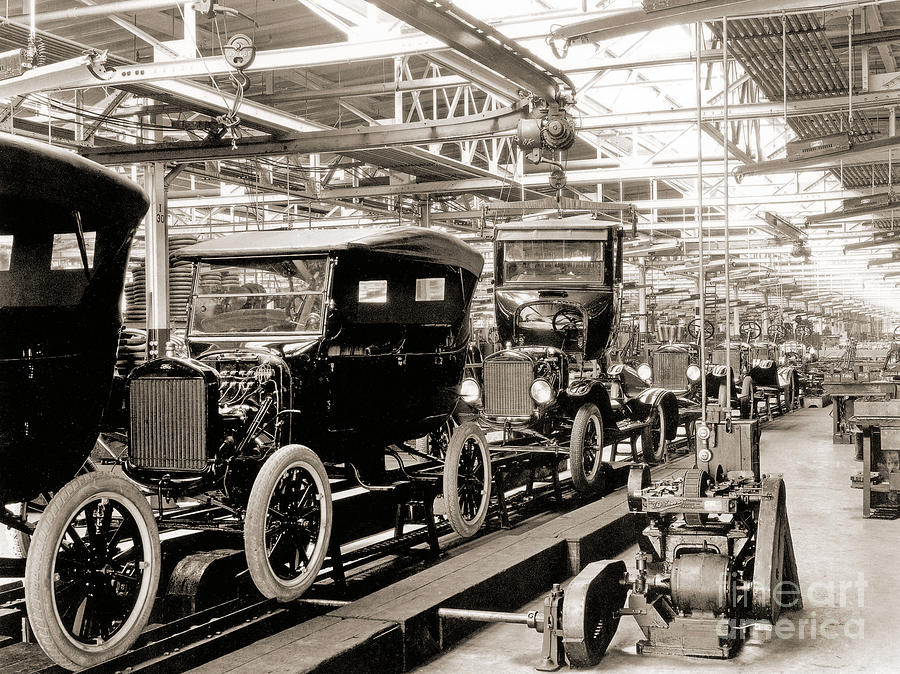

Impact on the Automotive Industry

One sector that witnessed a profound impact from assembly line practices was the automotive industry. Henry Ford’s implementation of the assembly line in his automobile plants revolutionized car manufacturing. The Model T, Ford’s iconic vehicle, became synonymous with mass production and affordability. The assembly line’s influence on the automotive sector set a precedent for industries worldwide.

Technological Innovations

As the 20th century progressed, technological innovations further enhanced American assembly lines. Automation, robotics, and sophisticated machinery became integral components of modern production processes. These advancements not only increased the speed of assembly but also improved precision and product quality. The marriage of technology and assembly line principles became a hallmark of American manufacturing.

Labor Challenges and Human Impact

While assembly lines brought unprecedented efficiency, they also posed challenges. Monotonous and repetitive tasks led to concerns about the well-being of assembly line workers. Labor movements and unions advocated for better working conditions and workers’ rights. Balancing efficiency gains with humane working conditions became a pivotal aspect of the ongoing dialogue surrounding assembly line practices.

Globalization and Assembly Line Dynamics

The principles of the American assembly line extended beyond national borders with the advent of globalization. American manufacturing practices influenced industries worldwide as countries adopted assembly line methodologies to boost production. The exchange of ideas and practices on a global scale further shaped the evolution of assembly line dynamics.

Challenges to Sustainability

While assembly lines have undeniably fueled industrial progress, there are sustainability challenges to consider. Mass production often leads to increased resource consumption and waste generation. Addressing these challenges involves incorporating sustainable practices into assembly line processes, promoting recycling, and exploring eco-friendly manufacturing materials.

Lean Manufacturing: A Contemporary Approach

In response to the environmental and efficiency challenges associated with traditional assembly lines, the concept of lean manufacturing emerged. Focused on minimizing waste and optimizing efficiency, lean manufacturing principles aim to create a more sustainable and streamlined production process. This contemporary approach builds on the foundations laid by the American assembly line while addressing 21st-century concerns.

Linking to American Assembly Lines

For a deeper dive into the history and impact of American assembly lines, visit American Assembly Lines. This resource provides insights into the evolution of assembly line practices, technological advancements, and their enduring influence on modern manufacturing.

Conclusion: A Legacy of Innovation

In conclusion, the American assembly line has left an indelible mark on the world of manufacturing. From its inception as a revolutionary concept to the integration of cutting-edge technologies, assembly lines have shaped the way products are made. Acknowledging their historical significance while embracing sustainable and innovative practices ensures that the legacy of American assembly lines continues to evolve in the dynamic landscape of global production.